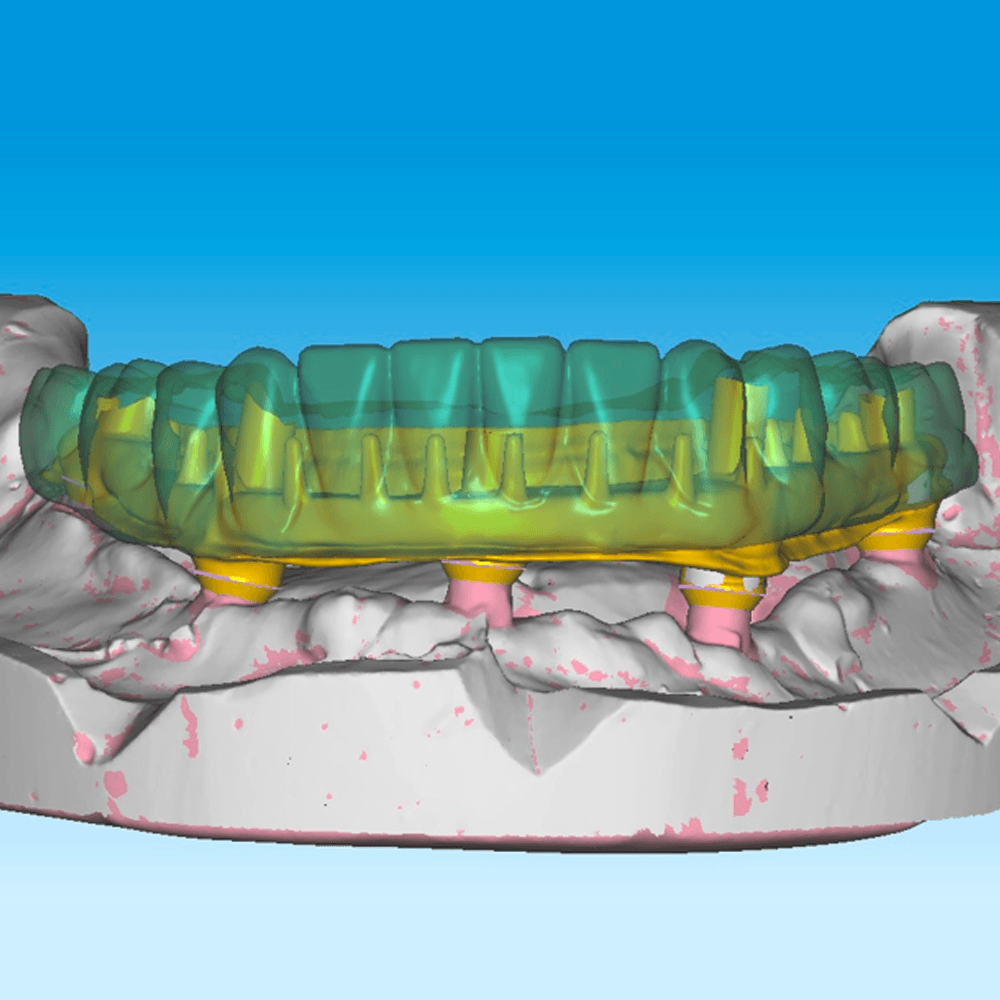

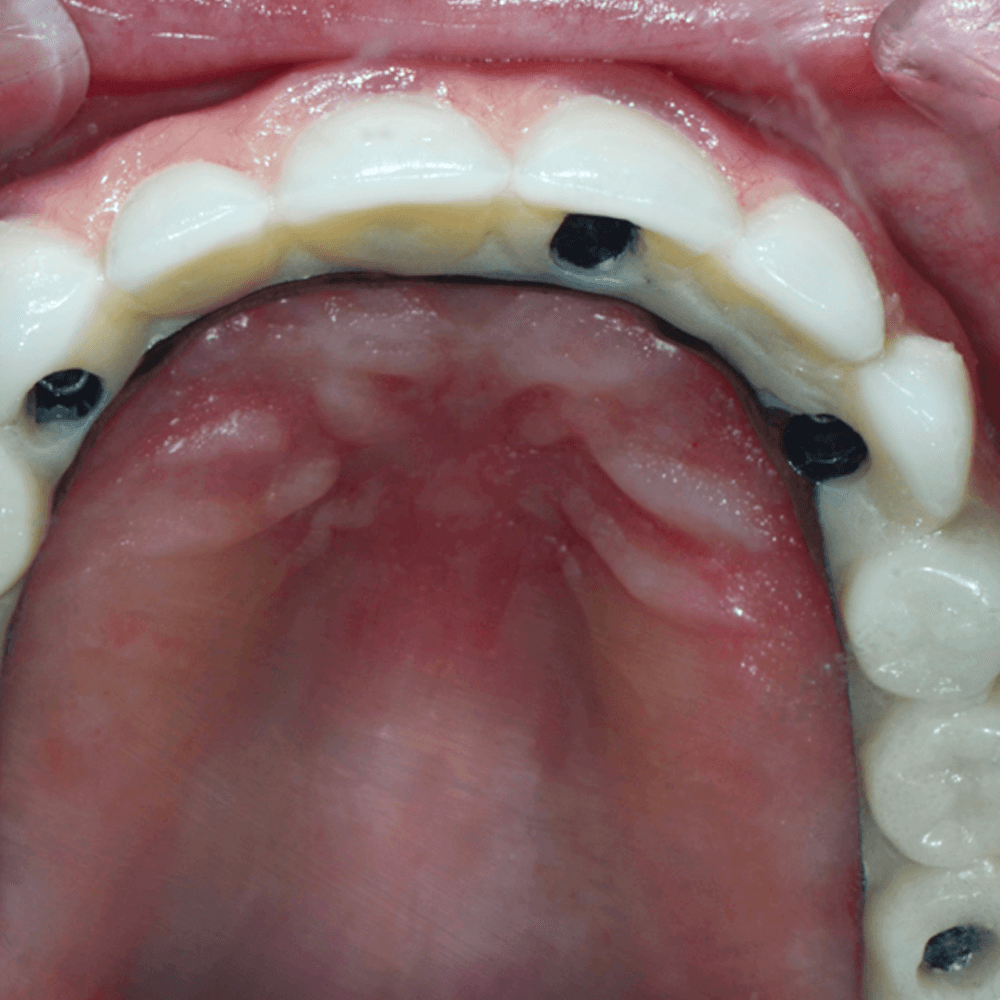

The Patient-Specific Bars approach allows for designing individual emergence profiles on each of the implant connections, perfectly following the patient’s gingival profile. This results in an aesthetic solution, since no metal will be visible in the mouth of the patient. Moreover, it improves the long-term functionality because the prosthetic material is actually enclosed in the small gap formed by the finish line. This avoids the occurrence of micro gaps or chipping of the prosthetic material around the implant connection. This also allows the Dental Team to “reline” the prosthesis to compensate for loss of bone and supportive tissue.

Preat Patient-Specific Bar Benefits

Patient Specific Designs

Our designs are endless. We do not use libraries or pre-determined shapes for our structures. All designs are customized to provide a unique structure for the individual patient and restorative team’s needs.

Freedom of Shape

The geometric freedom is achieved with the advancements and accuracy of CNC controlled machining to produce an excellent passive fit, without the shape limitations.

Personalized Restorative Solutions

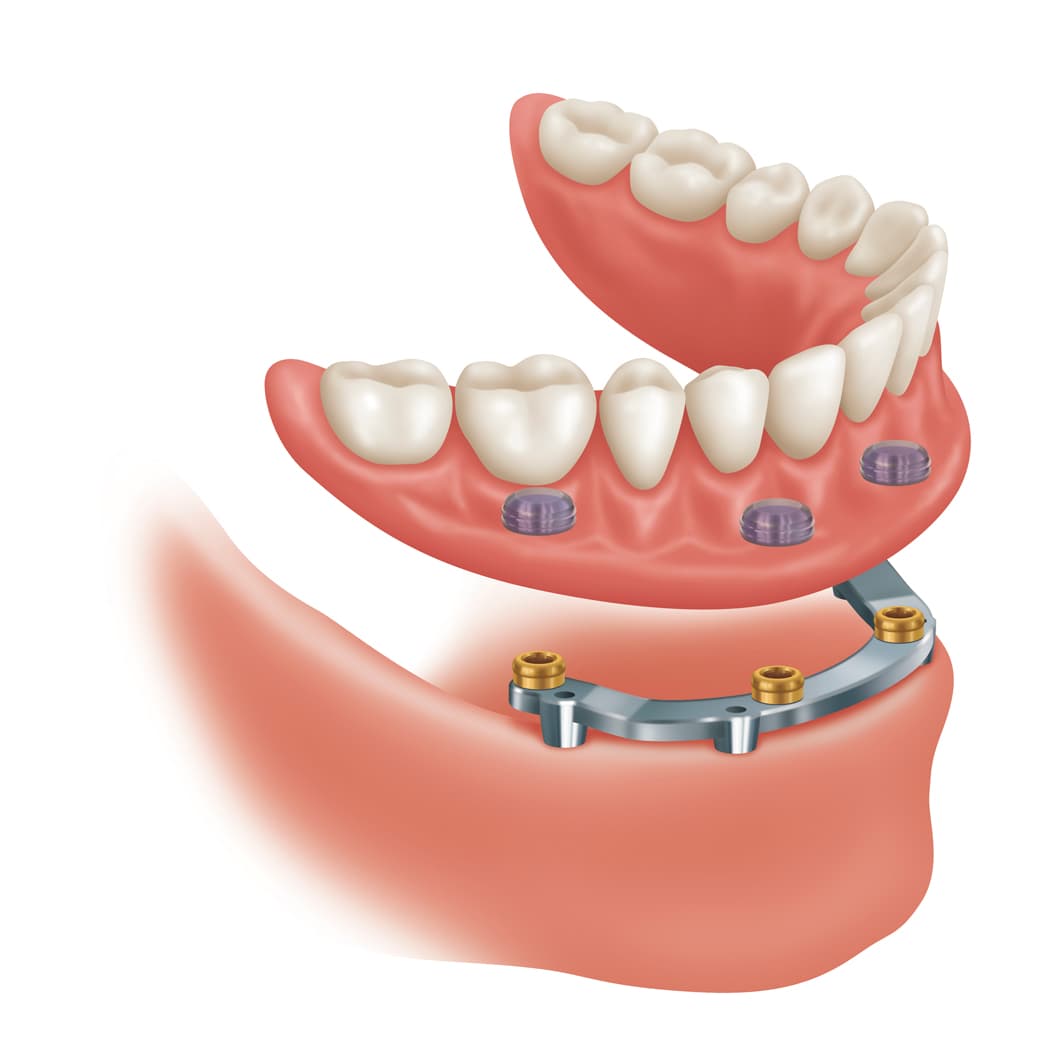

There is not a one-size fits all restorative solution for full-arch cases. We offer overdenture bar solutions for removable patients. We also have options for fixed patients including suprastructures for hybrids, thimble structure designs for individual crowns, or frameworks for stacking porcelain.

Our Designers are Technicians

Our designers have, on average, 20+ years at the bench. We understand dental terminology and the challenges that the restorative team faces. We are able to take our experience and use CAD/CAM to exceed customer expectations.

The Preat Patient-Specific Bar Process

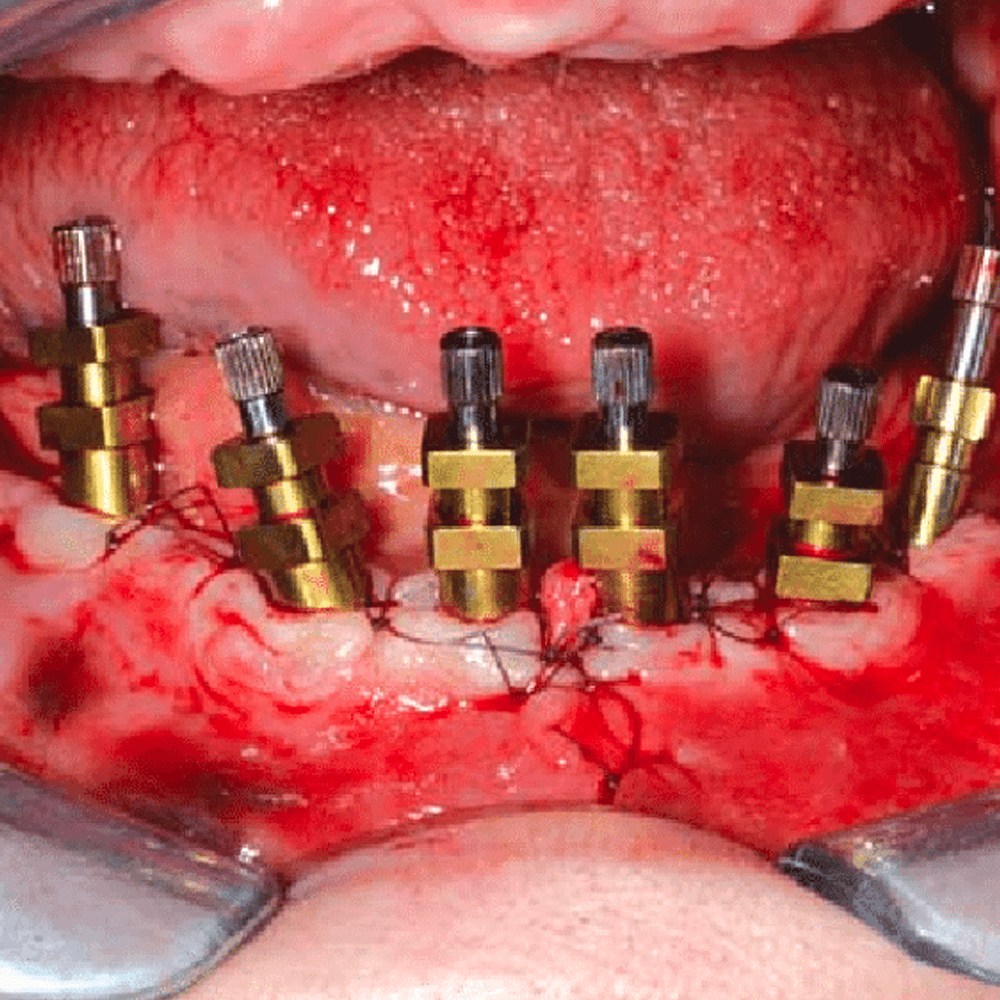

Take a fixture level or abutment level impression.

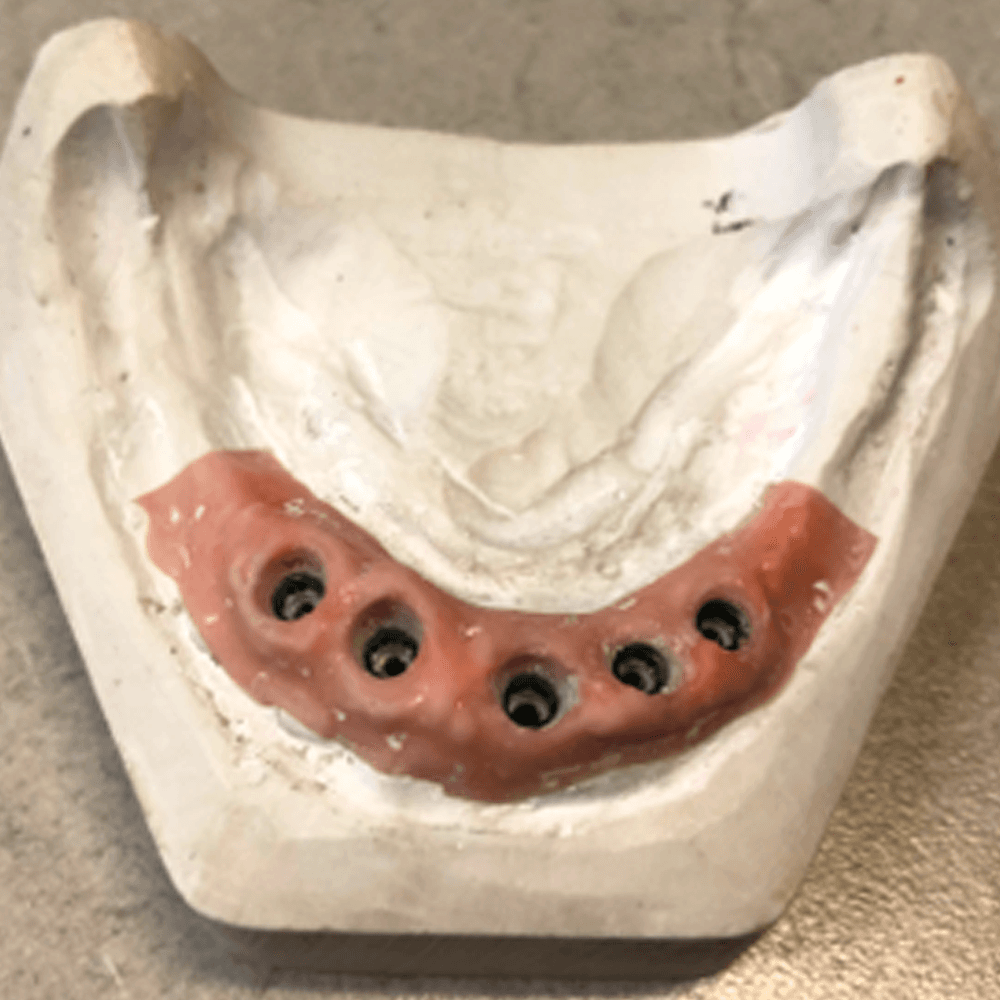

Pour Analog, soft tissue model.

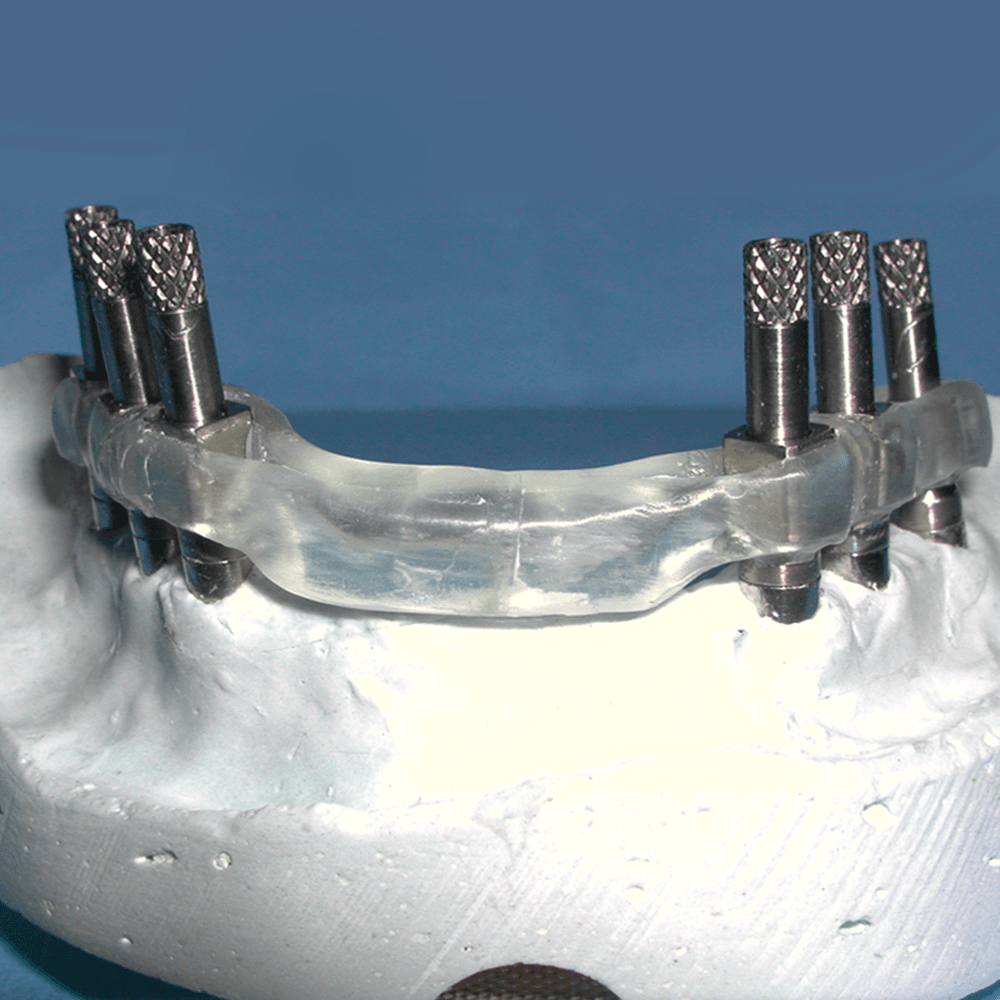

Make a verification jig, try in mouth to verify accuracy of master model.

Create a wax setup of proposed definitive restoration.

Send wax setup, master model, and verification jig to PRISM Design Center with the Rx completed.

Preat Custom Solutions Team Scans master model and wax setup.

Preat Custom Solutions Team Design technician will design patient specific implant suprastructure or overdenture bar depending on specifics of the Rx.

Preat Custom Solutions Team 3D rendering of digital design is sent to dental technician to review. Dental technician has the option to communicate changes to the design or approve the design.

Preat Custom Solutions Team After approval of the digital design, design is milled in titanium.

Preat Custom Solutions Team Stone model, wax setup, and titanium bar are shipped to dental technician.

Preat Custom Solutions Team Using laboratory processes, teeth are fixed to the bar in the final material of choice (determined by dentist and dental technician).

Preat Custom Solutions Team Patient has new teeth and a new smile!

Overdenture Bars and Attachments

LOCATOR® Bar Attachment

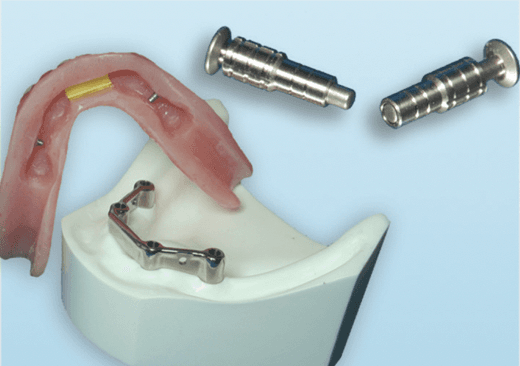

Hader Bar Kits and Components

Ackermann Clips & C118 clips

Clix Ball Attachment

Ceka and Ceka Revax

Universal Plunger Loc Attachment

Sagix Attachment

Titanium and Ceramic Chrome Cobalt

Preat Patient-Specific Bars are available in Titanium or Chrome Cobalt. Choose the alloy that is best for the individual restoration.

Preat Patient-Specific Bar Gallery

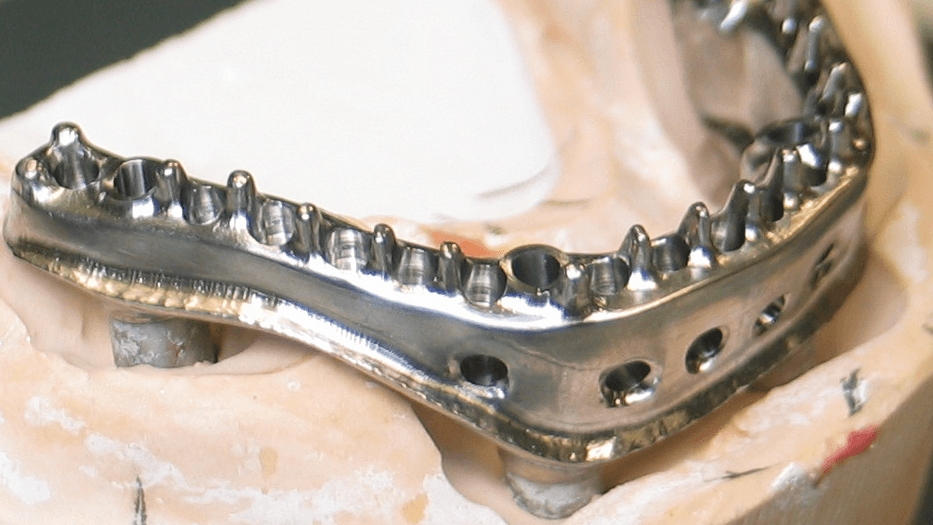

Hybrid with metal occlusion and metal linguals.

Hybrid with customized surface for mechanical retention.

Hybrid with polished lingual and lingual finish line.

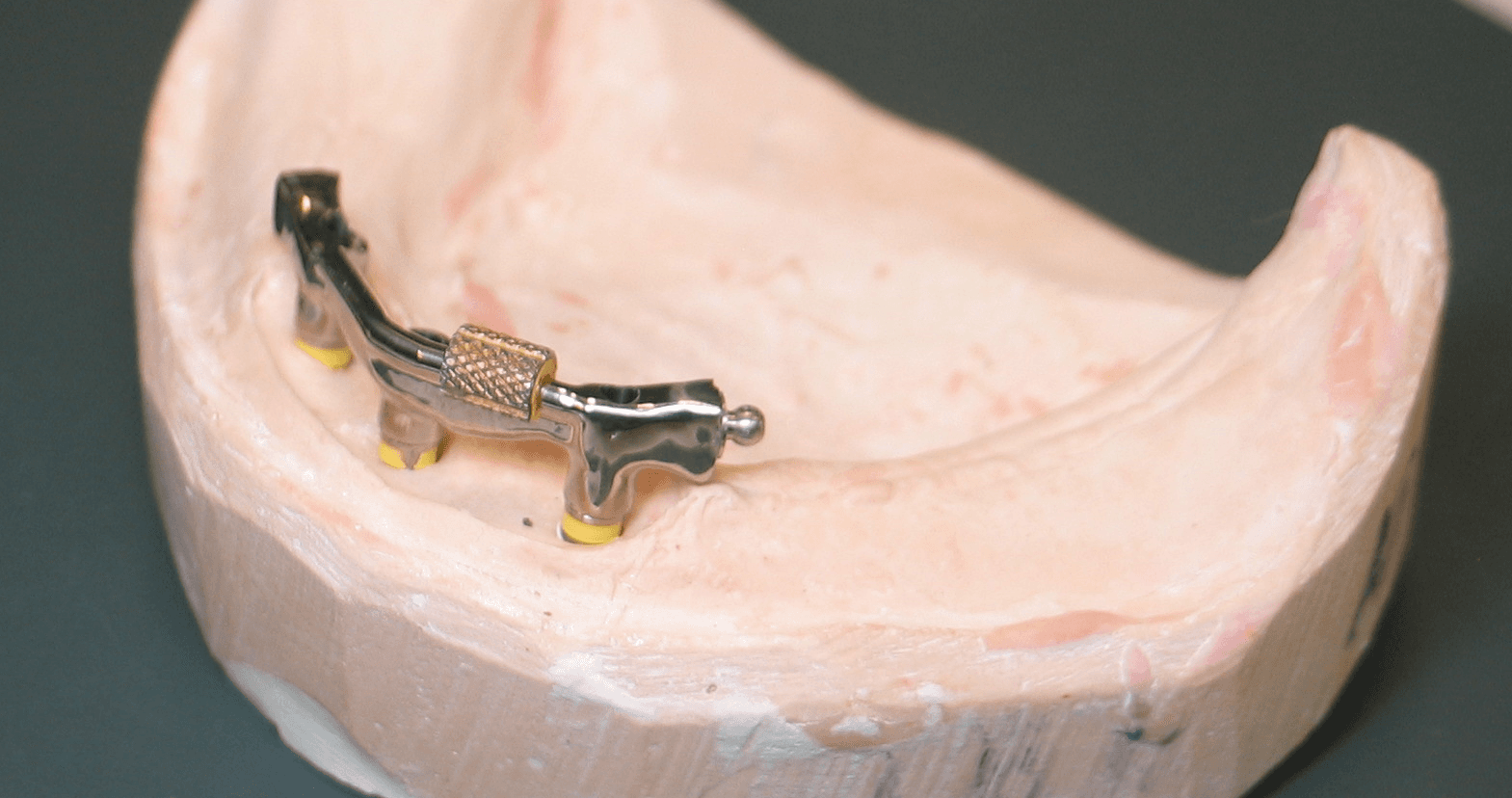

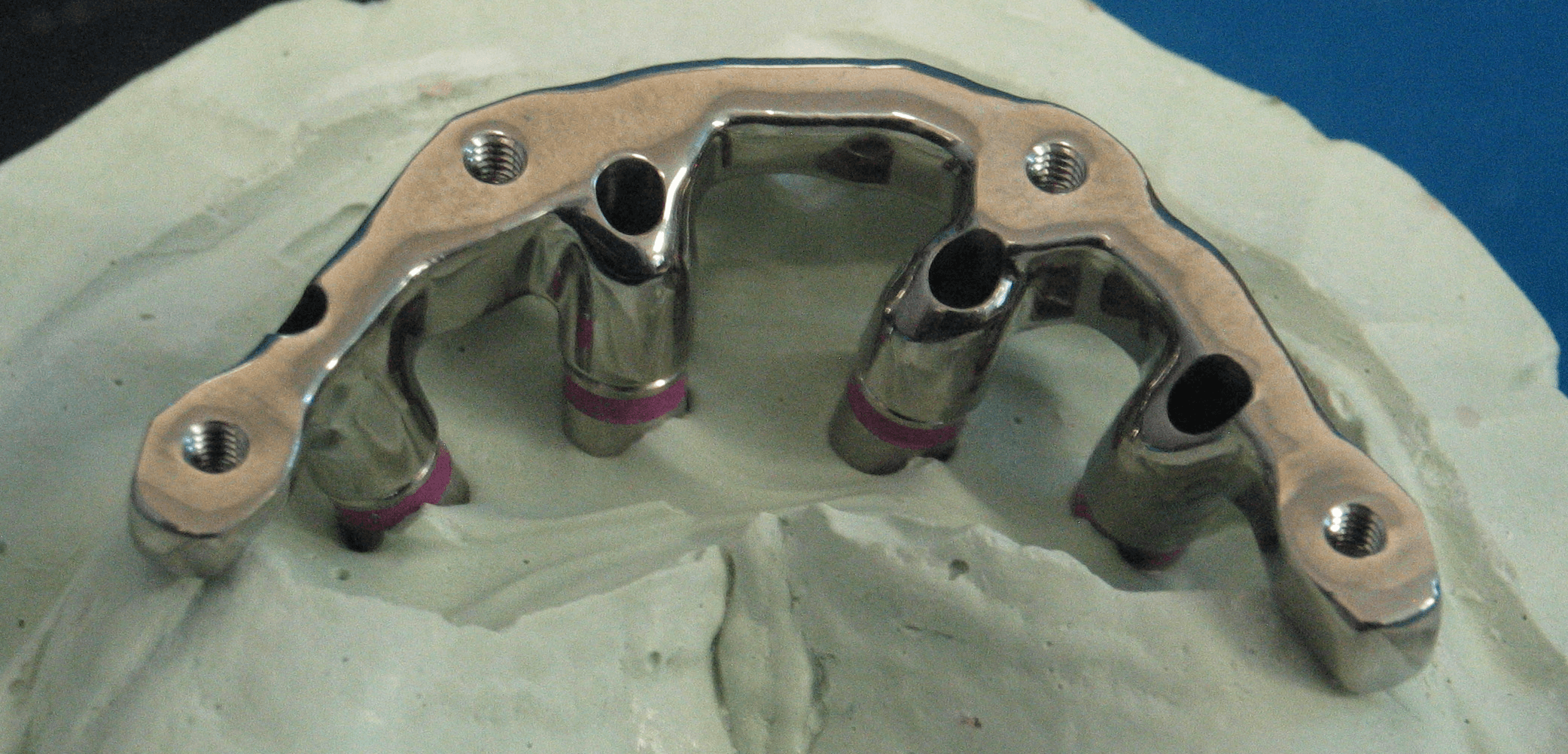

Overdenture bar for threaded Locators or Clix Attachments.

Hader Bar in the Anterior, Plunger Locs in the posterior.

Hybrid with Facial/Buccal finish line.

Mechanical retention!

Polished lingual with individualized scalloping for each tooth.