- Home•

- Categories•

- Product Information•

- Attachments•

- Fiber Technology•

- About Fiber Technology

Attachments

What Is It?

TriLor High Performance Polymer, Perma Fiber, Perma Mesh, and eFiber are scientifically proven solutions for Fiber Reinforcement of composite and acrylic resins. E-glass impregnated fiber studies have been published in over many different publications detailing the 15 years of research and hundreds of clinical cases in collaboration with both foreign and domestic universities.

Generation 1 Fibers

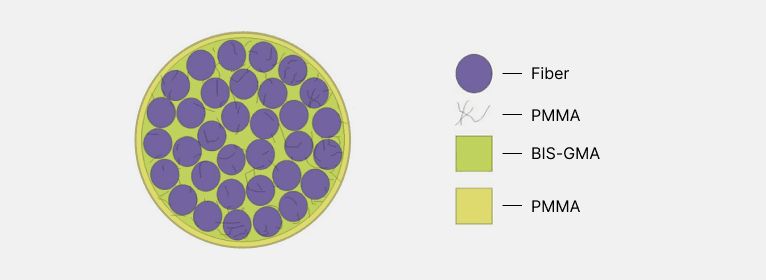

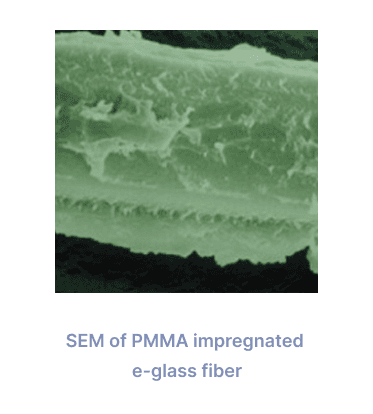

Perma Fiber and Mesh are revolutionary E-glass fibers. Each strand of this e-glass is computer impregnated with a PMMA (porous polymer) via a silane coupler that allows for bonding to all acrylic and composites. Perma Fiber is mainly indicated for indirect procedures.

Perma Mesh is indicated for both indirect and direct procedures.

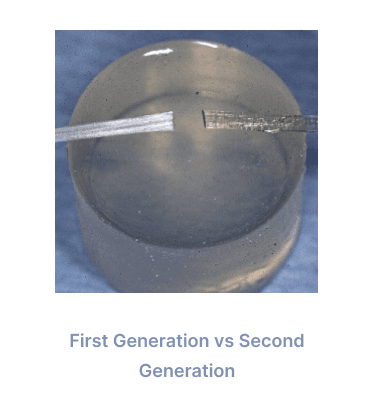

Generation 2 Fibers

eFiber is impregnated e-glass fiber with both PMMA and BIS-GMA (light cure) to allow the fibers to bond with light cure composites, acrylic, and etched enamel (28 MPa of strength).

eFiber is indicated for light cure indirect and direct procedures.

Why use fiber reinforcement?

- Prevent Stress Cracks from starting before they begin

- Increase fatigue resistance

- Increase flexural strength

- Improve Esthetics–the fibers are transluscent; no unsightly metal wires!

- Happy patients–eliminate broken prosthesis and non-revenue chairside time

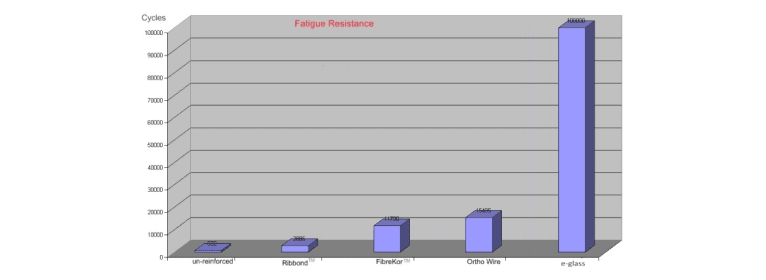

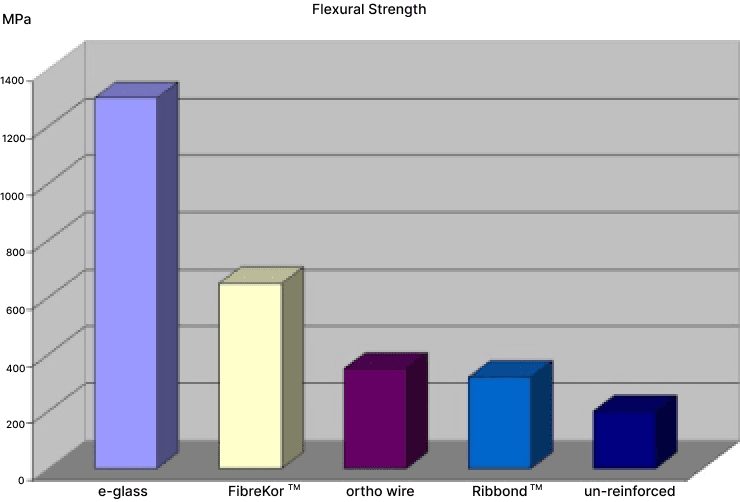

Adequate adhesion of the fibers to the polymer matrix is the most important factor for strength. Bonding requires proper impregnation of the fibers. Materials that bond result in a 100% strength increase in fatigue resistance and an 8x increase in flexural strength over non-reinforced materials. Fracture is a combination of fatigue and flexural stresses.

Adequate adhesion of the fibers to the polymer matrix is the most important factor for strength. Bonding requires proper impregnation of the fibers. Materials that bond result in a 100% strength increase in fatigue resistance and an 8x increase in flexural strength over non-reinforced materials. Fracture is a combination of fatigue and flexural stresses.

eFiber and Perma Mesh

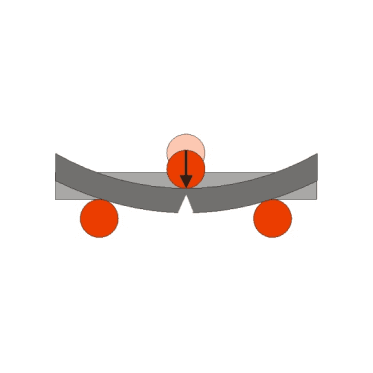

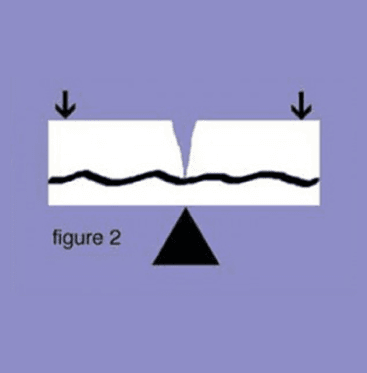

The three point bending test measures flexural strength.

Flexural strength is the amount of biting force a material can withstand before breaking.

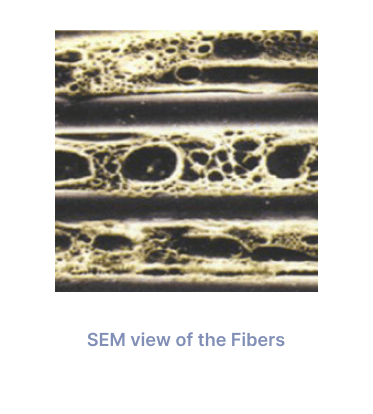

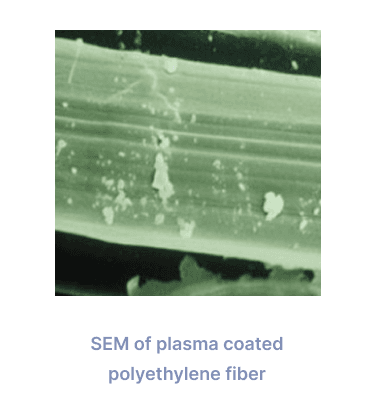

Polyethylene fibers, metal, and kevlar do not bond to polymers. These materials create two thinner, weaker, prone-to-break layers of polymer around the mechanically retained reinforcement. This gap between reinforcement material and polymer also harbors bacteria. The two SEM’s below show the bonding of impregnated e-glass fiber with polymer compared to the lack of bonding of plasma coated polyethylene fiber with polymer.

Where to use it?

The three major factors of successful reinforcement are:

- Position or Placement

- Bonding

- Direction and Bulk

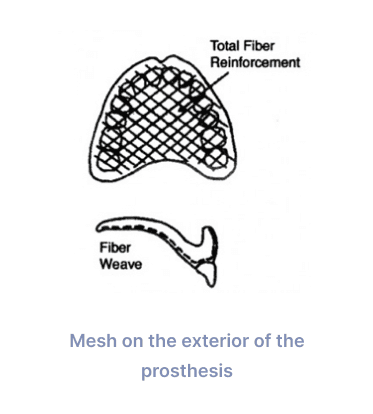

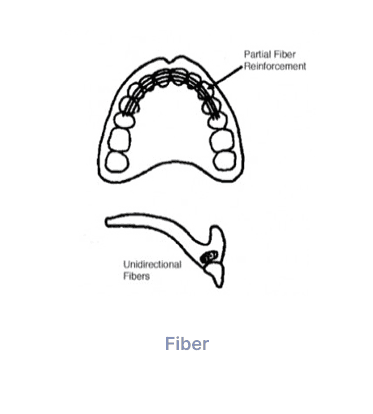

eFiber provides strength and rigidity, while Perma Mesh provides toughness to acrylic resin. When the direction of fracture forces is known, the use of unidrectional eFiber is recommended. Multidirectional Perma Mesh is to be used in very thin areas of polymer, or when the direction of forces are unknown.

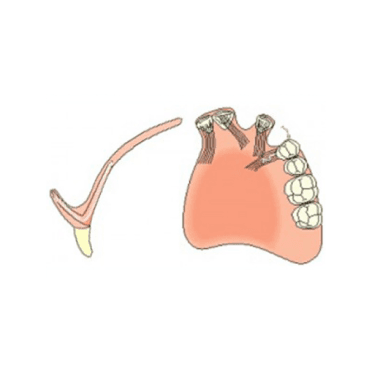

Position and Placement

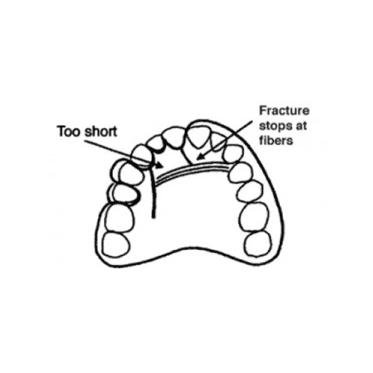

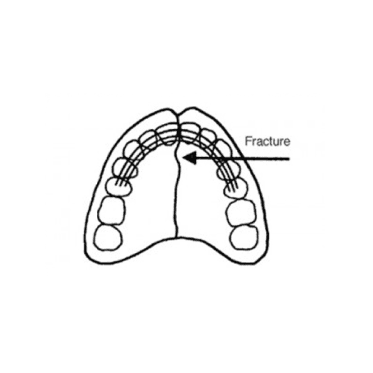

Place the fiber in the weakest area–for example, on dentures, this is often the midline area right beneath the teeth.

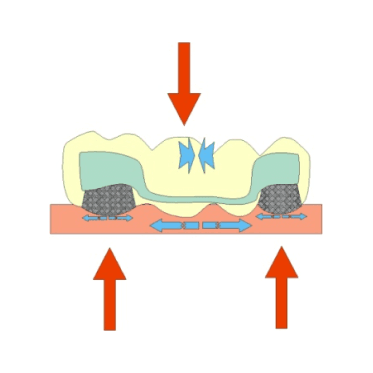

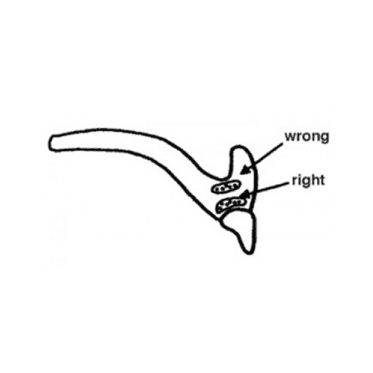

Reinforcement should be placed on the tension side during mastication, on the exterior of the prosthesis – not buried–and 90° to the destructive forces. For example, on a pontic, you want to reinforce the gingival (tension) side during mastication.

The “I Bar” design is the strongest. When one side is in tension, the other side is in compression (as shown on the left) and eliminate flexural fatigue.

The ability to aesthetically reinforce both aspects is unique to our impregnated e-glass fiber technology.

A stress fracture will continue to grow until it meets reinforcement strong enough to stop the crack.

A stress fracture will continue to grow until it meets reinforcement strong enough to stop the crack.

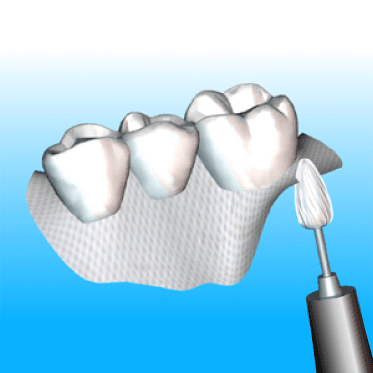

The translucent, aesthetic e-glass fibers allow for this optimum exterior placement–to stop the crack before it begins. The bonding and ability to grind and polish the fiber eliminate the annoying “fraying” of other reinforcement materials (FIG 1).

Materials that lack aesthetics and can not be polished–polyethylene, kevlar, metal–must be buried deep inside the prosthesis and do not materially increase (FIG 2) either flexural or fatigue strength.

Bonding

It is often assumed that the strength of the reinforcement alone increases the toughness of the polymer. Kevlar, metal, and polyethylene are all very strong materials. However, since they do not bond to polymers, these materials create a “sandwich” effect wherein the thin layers of polymer are actually weaker than before “reinforcement” and do not stop the stress fractures.

Adequate adhesion of the fibers to the polymer matrix is the most important factor for strength. Bonding requires proper impregnation of the fibers.

Bondable eFiber creates a laminating effect and become integral to the parent acrylic or composite resin.

The e-glass fiber allows the user to finish, polish, grind, reduce, and adjust the prosthesis. This allows for a smooth finish, eliminating a rough surface that will irritate the patient. This smooth finish also allows for superior hygiene, as bacteria adheres poorly to smooth surfaces.

Direction and Bulk

Fiber reinforcement should always be placed perpendicular to the potential fracture forces.

The unidirectional–such as eFiber–is stronger than mesh due to the bulk of fiber strands included in each bundle. The fiber is ideal when the direction of the stresses is known. For optimum results with the very thin Mesh, two layers of the Mesh are recommended, with placement also being perpendicular to the stress forces.

What are the advantages of Preat eFiber and Mesh?

- Strength (e-glass fibers and bonding!)

- Easy to grind and finish…stop breakage before it begins

- Bonding to all compositeand acrylic resins

- Light cure or self cure

- Two types of materials–mesh and fiber

- Easy to handle; no special tools needed—Improve productivity

- Great esthetics….materials are translucent when activated/wetted

- Chairside technique can be applied to limit the number of patient visits

When to use Fiber & Mesh?

- Repair of Full and Partial Dentures

- Reinforcement or Strengthening of New Full or Partial Dentures

- Reinforced “Flippers” or Other Removable Prosthetics

- Intra Oral Splinting

- Reinforcing the attachment area of an overdenture

- Thin palate maxillary dentures

- Non-invasive bondable esthetic temporary or provisional restorations for single tooth implants

- Reinforced temporary or provisional bridges

- Non-metallic “Maryland” type bridges

- Reinforced TMJ splints

- Reinforced sleep apnea appliances

- Reinforced and bondable orthodontic appliances

- Quick, easy and strong repairs of full and partial removable dentures

- Strong, bondable, reinforced inlay/onlay bridges

- Reinforced bruxism appliances and night guards

- Intra oral direct bonded periodontal splints (occlusal, lingual, or labial)

- Pedodontic space maintainers

All of the above procedures can be done with the eFiber starter kit. We strongly recommend using Perma Mesh and eFiber instead of Perma Fiber. The eFiber is much easier to handle, stronger, and can be easily light cured chairside or at the bench–it saves time!